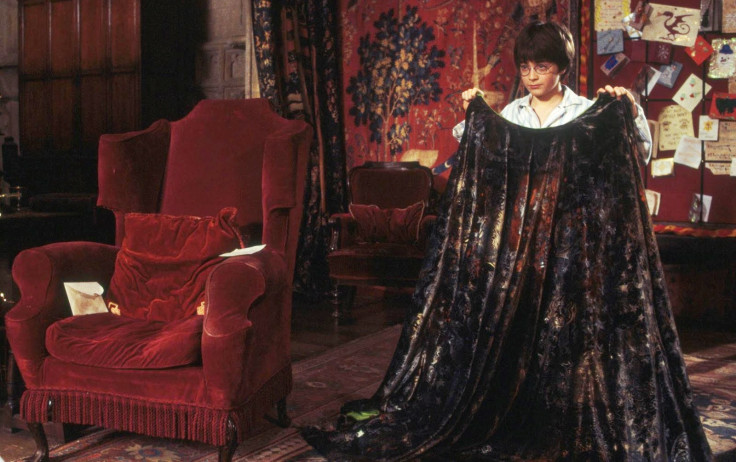

Invisibility cloak: Thin Harry Potter fabric design finally possible using dielectric materials

Computer engineers from the University of California in San Diego have succeeded in creating a cloaking device that could actually be made into a wearable fabric.

There has been a great deal of interest in the ability to make things invisible for generations, and every year scientists from research institutes around the world come up with new ideas.

However, so far researchers have only been able to make objects invisible by surrounding them with "lossy" technology designed to control, bend and scatter light waves away from the object, such as the Rochester Cloak made by the University of Rochester in New York or the invisibility box created by the German Karlsruhe Institute of Technology (KIT).

This technique is not great because the brightness of the light around the object is affected, highlighting that the object is there.

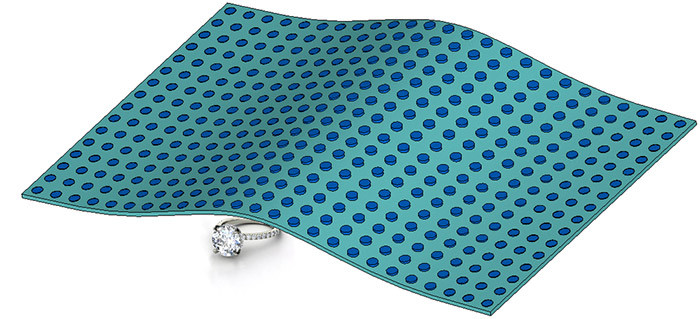

So UC San Diego researchers decided to design an extremely thin material that is able to make objects invisible, but doesn't alter the brightness of the light around it. The cloak is made from a thin light blue Teflon sheet embedded with multiple tiny cylindrical ceramic particles.

Their research, entitled Extremely Thin Dielectric Metasurface for Carpet Cloaking is published in the open-access journal Progress in Electromagnetic Research.

Hiding objects without affecting the light around them

"Imagine if you saw a sharp drop in brightness around the hidden object, it would be an obvious telltale. This is what happens when you use a lossy cloaking device," said Boubacar Kanté, a professor in the Department of Electrical and Computer Engineering at UC San Diego Jacobs School of Engineering and the senior author of the study.

"What we have achieved in this study is a 'lossless' cloak. It won't lose any intensity of the light that it reflects."

Both Teflon and ceramic are dielectric materials that do not absorb light and are not conductive, and the materials have been tailored into a cloak that is able to make an object placed on a flat surface look like it is not there at all, by changing the way light reflects.

"By changing the height of each dielectric particle, we were able to control the reflection of light at each point on the cloak," said Li-Yi Hsu, electrical engineering PhD student at UC San Diego and the first author of the study.

"Our computer simulations show how our cloaking device would behave in reality. We were able to demonstrate that a thin cloak designed with cylinder-shaped dielectric particles can help us significantly reduce the object's shadow."

Other ways to make an invisibility cloak

Apart from bending light waves, other solutions have been suggested. Researchers from Duke University, North Carolina, reported in March 2014 that they had succeeded using pyramid-shaped sheets of plastic and rerouted sound waves to hide objects.

The solution works underwater too and could be useful for submarines seeking to avoid being detected by an enemy's sonar system.

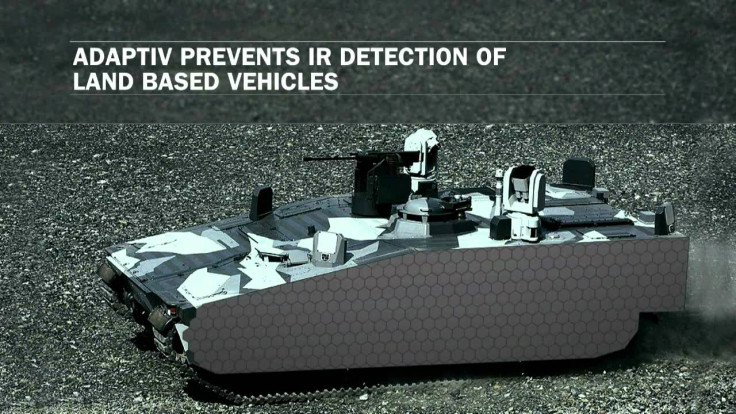

In 2011, BAE Systems and Swedish Defence Materiel Administration (FMV) patented a system that could turn tanks invisible using infrared cameras to broadcast an image on to a tank so that the vehicle matched its surroundings and became effectively camouflaged, but only in the dark.

The Adaptiv system is now ready to be sold commercially, but BAE is continuing to develop it so that the cloaking technology works on the human eye in broad daylight.

However, both of these solutions require a lot of bulky and heavy technology to achieve the required affect.

"Previous cloaking studies needed many layers of materials to hide an object, the cloak ended up being much thicker than the size of the object being covered," said Hsu. "In this study, we show that we can use a thin single-layer sheet for cloaking."

Another group of researchers led by the University of Central Florida have also been working on a material-based solution to the invisibility cloak problem, but they are using artificial nanostructures called "metamaterials" made from silver and dialectic composite films stacked in a 3D architecture.

The downside to this solution is that it is also a lossy solution that affects brightness around the object, and at the moment, it is incredibly expensive to produce large amounts of the metamaterial needed to cover and object to make it invisible.

© Copyright IBTimes 2025. All rights reserved.