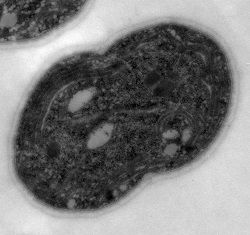

Genetically modified microalgae could become sun-powered drug production factories

Microalgae has been genetically modified to produce a variety of chemicals by harnessing energy from sunlight. Researchers say that while the technology to produce compounds on a large-scale is still some way off, it has the potential to produce cancer drugs continuously, sustainably and for a lower cost than current methods.

A team from the University of Copenhagen genetically modified a strain of microalgae so it produced secondary metabolites (organic compounds produced by a plant that are not needed for normal growth, development or reproduction). Some secondary metabolites are "high value compounds" and can be used in drugs and flavourings. But producing them normally requires enzymes involved in drug metabolism.

In their latest study, published in the journal Metabolic Engineering, researchers showed how the microalgae could be turned into mini chemical factories, producing compounds just by using energy from the sun. Engineered strains produced compounds after less than two weeks of cultivation.

Agnieszka Janina Zygadlo Nielsen, one of the study authors, said: "Basically, the idea is that we hijack a portion of the energy produced by the microalgae from their photosynthetic systems. By redirecting that energy to a genetically modified part of the cell capable of producing various complex chemical materials, we induce the light driven biosynthesis of these compounds."

Sustainable and continuous production

Researchers say their proof of concept work means sunlight can be transformed into a wide variety of chemicals that could be used in chemotherapy, bioplastics and compounds for flavour and fragrance.

This, they say, would mitigate current production problems including the high cost and complexity. "A cancer drug like Taxol for instance is made from old yew trees, which naturally produce the substance in their bark. It is a cumbersome process which results in expensive treatments. If we let the microalgae run the production this problem could be obsolete," Nielsen said.

"If we can create a closed system that produces the valued chemicals from water, sunlight and CO2, it would be a fully competitive method compared to the ones used today, where it is primarily extracted from plants or yeast and E. coli bacteria producing the substances. In theory it should be cheaper on the long run to use our method than adding the large quantities of sugar that the conventional yeast and E.coli cultures amongst other things need to function."

Thiyagarajan Gnanasekaran, one of the study's authors, added: "Theoretically, the water could be replaced with sewage water, which could make the process run on entirely renewable energy and nutrient sources."

Limitations in quantities produced

At present there are limitations to the work – for example, the microalgae uses a lot of the energy from the sunlight to run its own metabolic processes. This means it is difficult to produce high quantities of the useful compounds.

"[The microalgae uses] a large amount of the produced energy for themselves, since they are fully photosynthetic organisms," Gnanasekaran said. "Exactly for this reason, it makes good sense to have them produce the particularly valuable substances which are cost-effective to produce in relatively small quantities at a time, as for instance medicine."

© Copyright IBTimes 2025. All rights reserved.