New adhesive technology could reduce amount of waste destined for landfills

A group of researchers have reportedly created a new type of adhesive that can be removed with the help of magnets.

Thanks to companies and manufacturers promoting environmental awareness, more people are becoming advocates of recycling. Experts are coming up with new ways to reuse various materials, but most industrial adhesives make it difficult to separate non-recyclable parts from those that can be salvaged. This often leads to people dumping these items into landfills. However, reports claim that a new type of glue can help reduce unnecessary processes that can contribute to pollution.

The news comes from ScienceDaily, which credits this latest discovery to the researchers at the University of Sussex. The team believes their project can have a lasting impact on the manufacturing industry. Items such as car dashboards, mobile phones, microwaves and other similar products will be easier to disassemble for recycling purposes.

Right now, depending on the type of glue, dismantling bigger chunks of waste may not be possible. On the other hand, the new adhesive in question can quickly melt with the help of an alternating magnetic field. Hence, pieces come apart quickly and supposedly with barely any residue. Dr. Barnaby Greenland, one of the members of the aforementioned research team, claims it can attach to metal, wood, glass and plastic with ease. Moreover, its bonding strength is allegedly on par with most industrial offerings.

Traditionally, some adhesives can be removed by subjecting it to high temperatures using an oven or heat gun. Depending on the size of the object or the material it's using conventional methods are rendered unusable. Hence, the new alternative promises convenience with the help of magnets. "in as little as 30 seconds, we can unstick items in a relatively weak magnetic field," said Dr. Greenland.

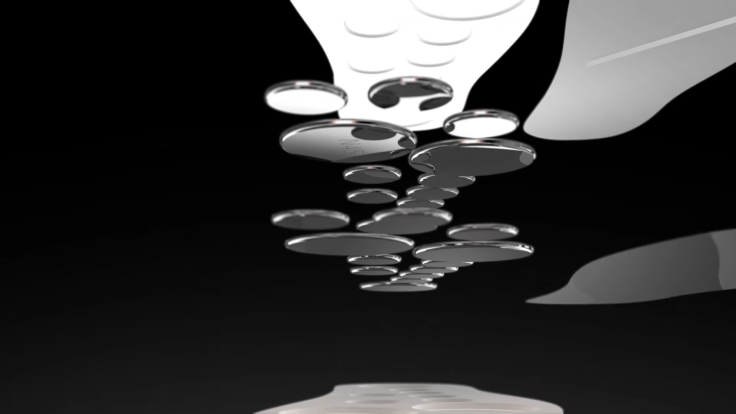

What makes this innovative process remarkable is the presence of tiny metal particles mixed into the glue. Using an inductor, recycling stations can cause the metallic bits to generate heat, thereby melting the adhesive. The team proposes a scenario wherein a conveyor belt carries items that need to be deconstructed through a magnetic field. This appears to be an efficient solution to improve the material recovery rate. Furthermore, since there is no direct heat applied at any time, it is essentially a safer option, according to the researchers.

© Copyright IBTimes 2025. All rights reserved.