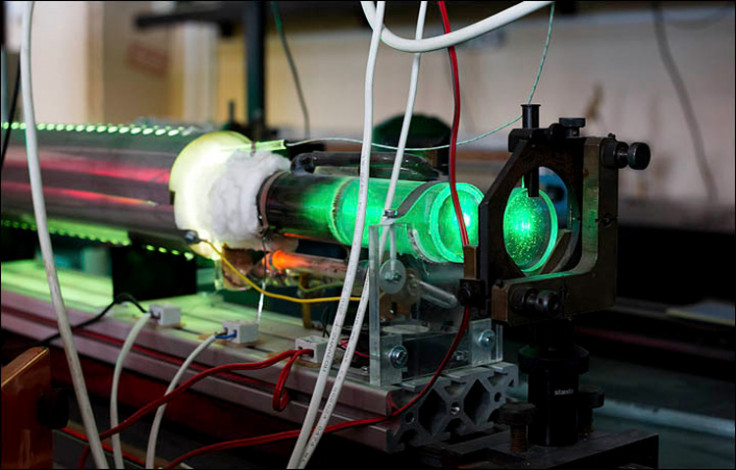

Revolutionary metal vapour laser cuts bone and smartphone glass without burning it

Russian researchers at the Tomsk State University in Siberia have developed the world's first metal vapour laser that can cut materials without burning them and is usable in a wide number of different industries.

The new laser utilises strontium vapour and works by vaporising the metal from a solid state to a gaseous state at a high temperature. It is able to operate at a wide range of different wavelengths, such as 6.45 microns, which is the optimum range for medical laser surgery cutting live human tissue and bones.

Because the laser can operate at different wavelengths, unlike other lasers which need to be built for a specific purpose, the Tomsk laser can be used by geologists to analyse the gas composition of the atmosphere, but also to cut glass for mobile devices such as smartphones and tablets.

World's first metal vapour laser

"There is no such laser anywhere else in the world, and there is a lot of interest in it," Professor Anatolyi Soldatov, dean of the Innovative Technologies department at Tomsk State University, told the Siberian Times.

Now, a number of major companies and universities are keen to partner with the researchers, including tech giant Samsung and the Wuhan University of Technology in China.

"We tried our laser to cut glass that Samsung Electronics sent us. It turned out that the strontium vapour laser is the best for cutting and it's not a mere coincidence," said Soldatov.

"Industrial devices use carbon dioxide lasers with a 10.6 micron wavelength. It doesn't go through the glass, but instead focuses on it and heats it. Eventually, 20% to 30% of the glass cut this way can't be used because of the small chips forming during the procedure."

Tomsk State researchers found that glass imperfections are a hundred times smaller using the strontium vapour laser to cut the glass, compared with using a carbon dioxide laser.

Laser breakthrough has taken decades

"Russian scientists started working in this area earlier than the rest of the globe, and the first papers on copper vapour lasers were published in Russia. Our research group also made significant scientific results in this direction," said Soldatov, adding that the theory for the laser was developed by Tomsk State University half a century ago in the 1960s.

Then in 1982, a paper was published about the Light Identification Detection and Ranging (LIDAR) laser that was built for the Russian military. Unlike the LIDAR lasers commonly used today in countries like the UK and the US to create 3D models of the Earth, the Russian laser was made from strontium vapour.

It was used to measure the concentration of water vapour on Lake Balkhash, but then the invention was forgotten about until academics from Vanderbilt University in the US began researching the best wavelength for drilling bones and cutting human tissue to embed implants in the early 2000s.

"After that, the Americans began to wonder whether there were any lasers in the world at this wavelength but are smaller than the free-electron laser. They found our old publication from 1983 and they found us," Soldatov said.

"Obviously, it was necessary to improve it, and now we're developing the technologies for cutting live tissue and working on optimising the laser, the shortening of the pulse duration to a few nanoseconds, increasing the energy density."

© Copyright IBTimes 2025. All rights reserved.