Chemical Engineers Create Affordable Artificial Kidney From 3D Printed Parts

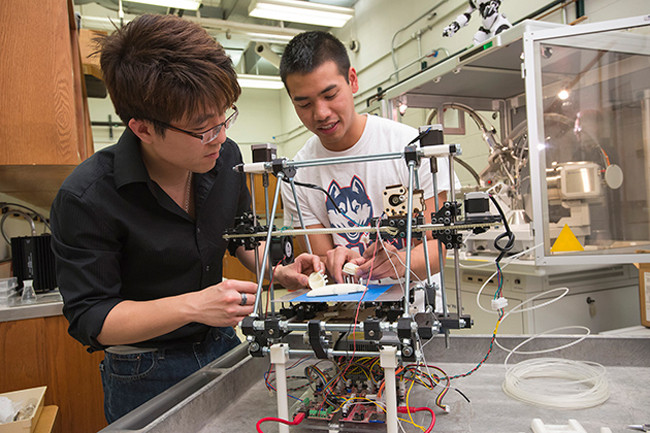

Chemical engineering students from the University of Connecticut have developed a prototype for an artificial kidney that makes use of 3D-printed parts and hollow fibre membrane technology.

Partnering with commercial 3D printing company ACT Group, senior chemical engineering students were challenged to create an artificial kidney within a year for their senior design project using 3D-printing, which is different from the recent practice of bio-printing organs using living cells.

One of the teams decided to focus on using hollow fibre membrane technology to imitate existing hemodialysis, a method that removes waste products such as urea, creatinine and free water from the blood when the kidneys are in a state of renal failure, according to UConn Magazine.

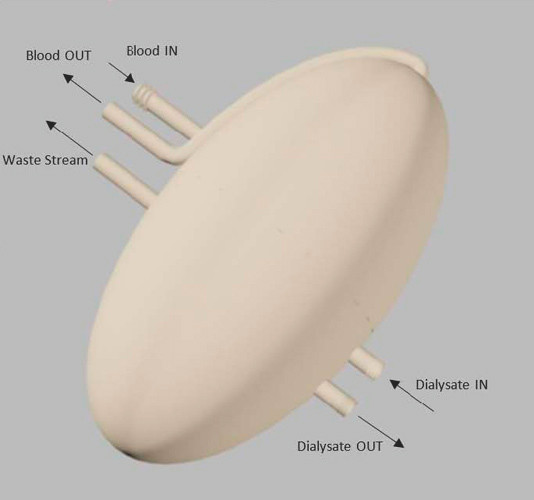

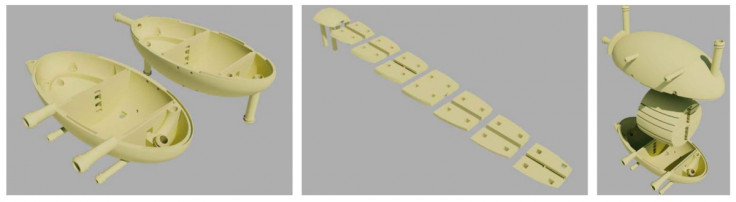

Using AutoCAD software, they designed a kidney shell with five pipes leading out of it that can be used to filter the blood.

Long waiting list for a new kidney

In the UK, 3,000 kidney transplants were carried out from April 2012 to April 2013, according to the NHS, but there were still over 6,000 people on the waiting list for a transplantable kidney.

The rate of kidney disease is particularly high amongst people of African, South Asian and Caribbean ethnic origin and there are not enough donors coming forward from these communities.

"The objective of the design project is to get these students to combine the latest technology and their chemical engineering knowledge, learned over their four years at UConn, to solve a technical problem where we can make a difference," said Dr Anson Ma, assistant professor in the Department of Chemical and Biomolecular Engineering and the Institute of Materials Science, who oversaw the research.

At the moment, 3D printers do not print in a low enough resolution in order to print a complete structure to filter the blood, so the team is using hollow fibre membranes installed within the shell to filter the blood.

Hollow fiber membranes

Hollow fibre membranes range from being smaller than a single strand of human hair to measuring several hundred microns in diameter.

They come tightly bundled together and have been used successfully to filtrate liquids in water treatment, swimming pools, fridges and the food and beverage industry, as the membranes are permeable, meaning that liquid can filter down through or run outside the membrane.

"Hollow fibre membranes will be installed on the inside to do the filtration function. The kidney will then be sealed together using the threads and sealing o-rings. A fluid called dialysate will be circulated on the outside of the membranes, inside of the shell, which will cause flux of components from the blood," explained team member Benjamin Coscia.

"The outside of the shell can be used as a substrate for growth of biological material for ease of integration into the body."

© Copyright IBTimes 2024. All rights reserved.