Carbon capture by new compound cuts energy cost by half

Scientists at UCB have found a material that can efficiently capture and remove carbon from any kind of environment and do it cheaply.

The compound then releases the carbon dioxide at much lower temperatures than current carbon-capture materials do cutting by half or more the energy consumed in the process.

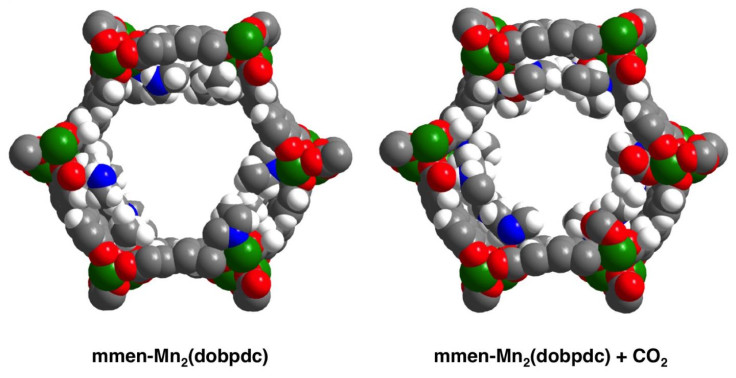

The material, a metal-organic framework (MOF) modified with nitrogen compounds called diamines, can be used in a range of applications to remove the greenhouse gas from the room-temperature air of a submarine or the hotter flue gases from a power plant.

"Carbon dioxide is 15% of the gas coming off a power plant, so a carbon-capture unit is going to be big," said senior author Jeffrey Long, a UC Berkeley professor of chemistry and faculty senior scientist at Lawrence Berkeley National Laboratory. "With these new materials, that unit could be much smaller, making the capital costs drop tremendously as well as the operating costs."

The diamine-appended MOFs can capture carbon dioxide at various temperatures, depending on the diamines used.

CO2 release

They can release the CO2 at just 50 C above the temperature at which the gas binds compared to the 100 C required in current compounds.

MOFs are composites of metals with organic compounds that form a porous structure with tiny, parallel channels to which the CO2 adsorbs.

The amines cause the CO2 to load into the material very quickly at a specific temperature and pressure, and then come out quickly when the temperature is raised by 50 C.

"When the first CO2 starts to adsorb at a very specific pressure, all of a sudden it facilitates more CO2 adsorption, and the MOF rapidly saturates. That is really a different property from any other CO2 adsorbent based on amines," says Long.

The diamines bind to the metal atoms of the MOF and then react with CO2 to form metal-bound ammonium carbamate which lines the interior of the MOF.

At a sufficiently high pressure, one CO2 molecule binding to an amine triggers other CO2 molecules to bind like a zipper running down the channel.

Power plants that capture CO2 today use an old technology whereby the waste gases are bubbled through organic amines in water, and the carbon dioxide binds to amines. This liquid is then heated to 120-150 degrees Celsius (250-300 degrees Fahrenheit) to release the gas, after which the liquids are reused.

The entire process consumes about 30% of the power generated.

Challenges of CCS

Current atmospheric concentration of CO2 is now 400 parts per million (ppm) and the IPCC and other organisations advocate bringing this to below 350 ppm before the end of the century to avoid irreversible climate change.

Carbon capture and sequestration (CCS) remains a popular form of mitigation of excessive carbon emissions into the atmosphere. But the technique has its problems.

Carbon sequestration techniques inject carbon dioxide into the subsurface some 7,000 feet below the Earth's surface where it can be stored in salty aquifers that can chemically react with carbon dioxide to solidify the gas eventually.

But a recent MIT study using computer modelling showed that a large part of the gas is not converted to rock but remains mobile and can return into the atmosphere with dangerous implications.

Globally, around 20 demonstration projects are expected to be set up by 2020, in various industrial sectors. But to date most CCS projects at coal power plants have been scaled back, delayed, or cancelled mostly due to high costs.

Transport issues and operational risks, such as seismic tremors have also been raised.

One large, coal-fired plant alone generates the equivalent of 3 billion barrels of CO2 over an average 60-year lifetime. This would require the equivalent of a major oil field to contain. The pressure could cause leaks or earthquakes, as shown in the 2010 Stanford and Duke university studies.

© Copyright IBTimes 2025. All rights reserved.