Find out how Nasa's telescope testing tech can make cars safer

Vibration machines that were first built for Nasa are now standard for most manufacturing industries.

Of the several technologies developed by Nasa for its space missions that eventually made their way to other industries, the shake test could be considered among the more unconventional ones.

Nasa tests all its spacefaring equipment from large telescopes to small satellites by shaking them violently on vibration tables to ensure their sturdiness. According to a Nasa release, the vibrations are delivered through specially made machines that can deliver up to 100,000 pounds of force.

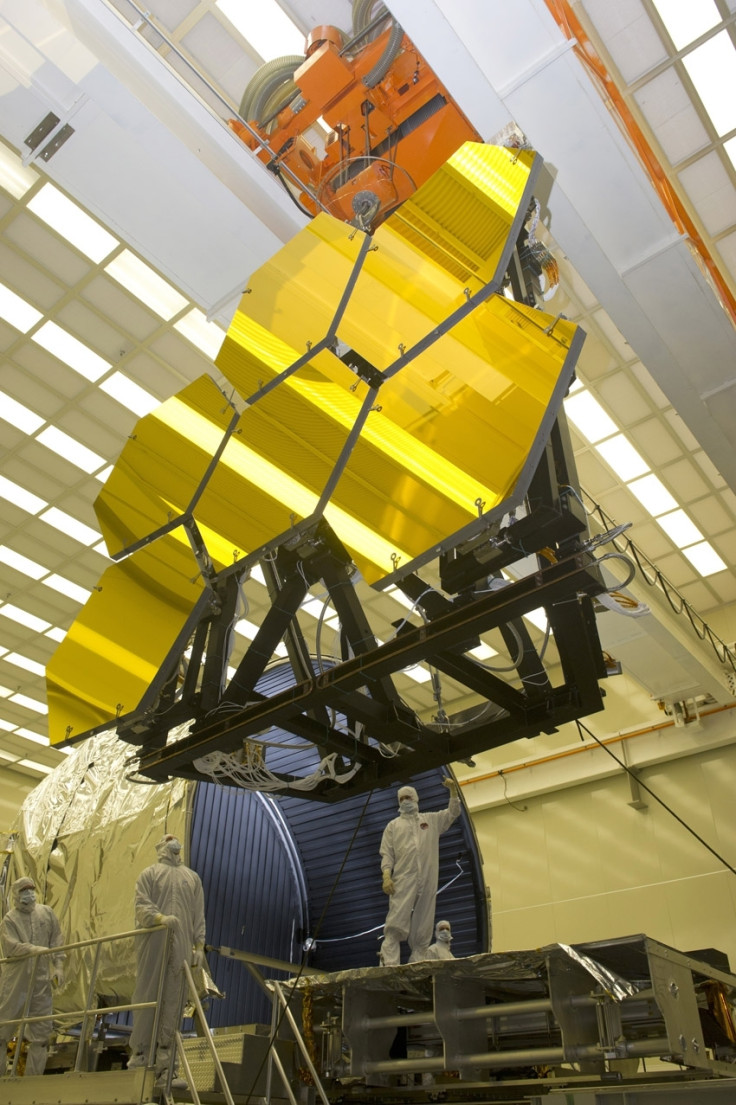

Even millions of dollars worth precision instruments like the James Webb Telescope will be put through shake tests before they can be flown into orbit so that any component that can break or malfunction can be identified and fixed right away. In case there is a breakdown in space where the telescope that succeeds Hubble will be placed a million miles away, it might become impossible to fix.

"The Webb" as Nasa calls its telescope is made with 18 intricately engineered mirrors and carefully calibrated sensors, all of which will be tested by violently shaking the 14,300-pound weighing device, making sure everything is properly in place.

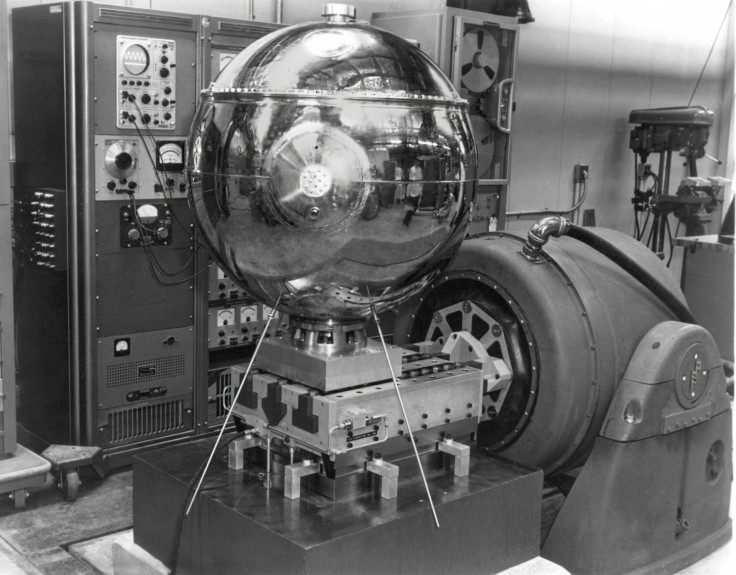

Vanguard 1, the oldest still operational satellite in orbit was launched in the 1950s and the first shake test was done just before launch of this satellite, according to Nasa.

This technology and testing method soon trickled down to other industries as well.

A private company under contract with Nasa called Team is reported to have been pioneers in this field. It developed a type of bearing called the T and V bearing that helped it create its very first vibrating table which was able to recreate the stresses of rocket launches leading to effective testing.

Apart from simulating a rocket launch, Team was also able to recreate other trying conditions like earthquakes and bumpy roads. The test became a good way to see how well a structure can hold up against the stresses of wear and tear over a lifetime of use.

Nasa says updated versions of the same Team technology used in testing satellites from the 1950s are now employed by major car makers to test the safety of their vehicles. Every component from valves to passenger seats is put through a thorough shaking.

End of the line testing is done for fully built cars with vibrators placed beneath each wheel. Nasa says that companies like Ford regularly test their vehicles this way to ensure their products remain in place, together and perform for thousands of miles.

"We've evolved this in-house knowledge that Nasa has been fundamental in helping us develop, and we bring that to bear on all our products," said Curt Nelson, a member of Team Corporation's aerospace and military sales division.

© Copyright IBTimes 2025. All rights reserved.