New Motor Design Promises Reduced Cost and Increased Efficiency

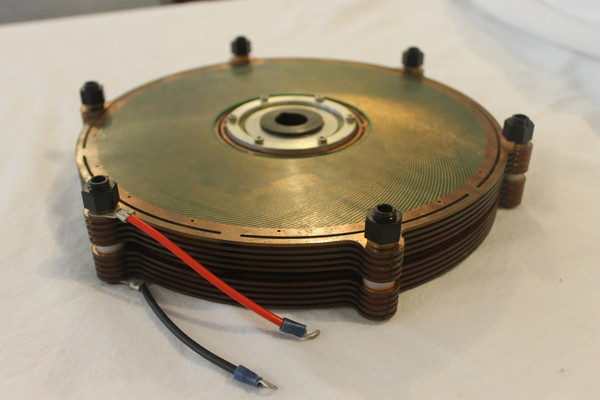

A table-top motor that works on electric fields instead of magnetic fields promises to deliver major advantages in weight, cost, efficiency and maintenance requirements.

The new design being developed at UW-Madison avoids the use of costly rare earth metals and substitutes aluminium in place of expensive copper used in conventional motors and generators.

An electric voltage delivered to the fixed plates creates an electrostatic field that attracts the rotating plates and causes them to spin.

"A charge builds up on the surfaces of the plates, and if you can manipulate the charge, you can convert electricity into rotary motion or transfer electric power from one set of plates to the other," says Dan Ludois, an assistant professor at UW, who developed the idea.

Such motors have been advocated and built way back in the 19th century but magnetism has been easier to work with due to naturally occurring materials with the required properties. However, with material research it is hoped that electrostatic current based motors can offer advantages.

The technique relies on electronics that controls a high-voltage, high-frequency electric field and fluid mechanics to keep the surfaces close without touching.

The first application of the invention may be a generator for wind turbines, an application for which the company C-Motive Technologies has received a research grant from the US National Science Foundation.

© Copyright IBTimes 2024. All rights reserved.