New 'spray-on' memory could turn clothes and accessories into digital storage devices

Programmable electronics could soon be everywhere thanks to new type of flexible, low-cost memory.

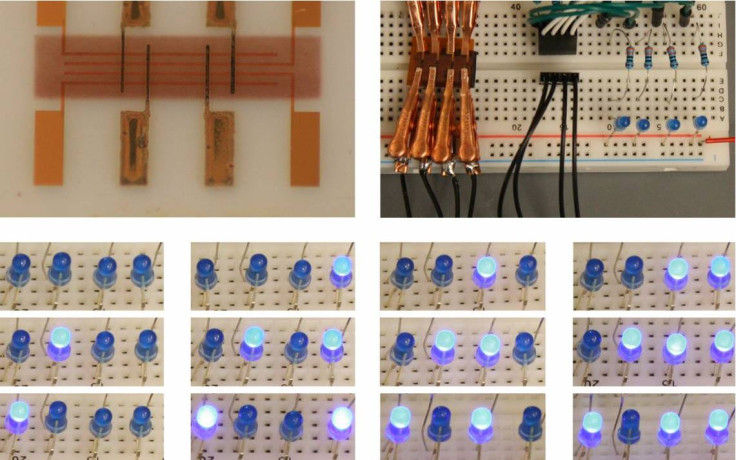

Scientists have developed a new type of "spray-on" digital memory that could be used to turn everyday items into programmable electronics. The device, which is roughly the size of a postage stamp, was created using 3D printing by researchers at Duke University in Durham, North Carolina.

The technology is comparable to a four-bit flash storage drive and is flexible, meaning it could be used to add low-cost digital storage to paper, plastic and items of clothing. While it isn't enough to store films or music, it could be used for environmental sensors, trackable RFID tags and "in applications where low cost and flexibility are key," the researchers said.

This includes sensors that could be applied to groceries or medicine bottles to ensure they were being stored at the right temperature.

Key to the technology is a new type of material made of silica-coated copper nanowires that can be sprayed onto material through aerosol jet printing, a type of 3D printing method for electronics.

Applying a small voltage to the material allows a weak electric current to run through it and switch the device between high and low-resistance states. The researchers claim the write speed of the device is around three microseconds, which is comparable to the speed of flash drives.

Flexible electronic components could eventually allow manufacturers to build smartphones and tablets that can be fully flexed and even rolled up. Samsung has teased such concepts in the past, although the technology as the manufacturer envisions it is still some way off.

While other research groups have created similar printable memory devices in recent years, Duke University claim to be the first to create one suitable for real-world use.

"We have all of the parameters that would allow this to be used for a practical application, and we've even done our own little demonstration using LEDs," said Matthew Catenacci, Duke University student and research author.

"We have developed a way to make the entire device printable from solution, which is what you would want if you wanted to apply it to fabrics, RFID tags, curved and flexible substrates, or substrates that can't sustain high heat."

© Copyright IBTimes 2025. All rights reserved.