Mind the gap – Industry 4.0 and the future of manufacturing

The manufacturing industry, in common with many others, is currently undergoing a significant digital transformation.

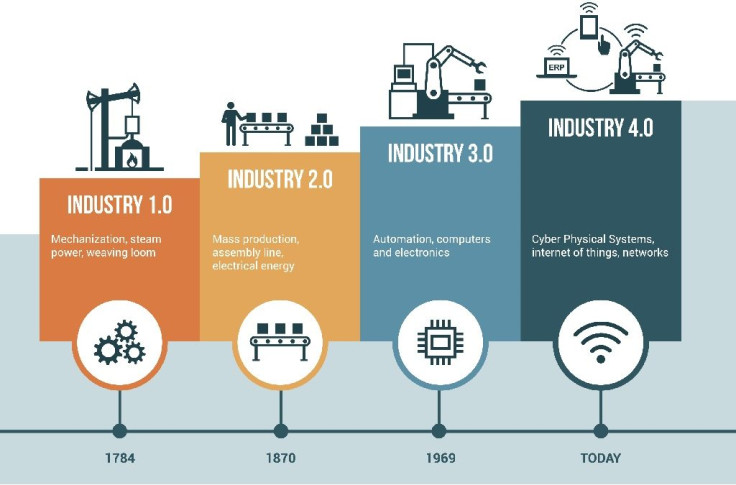

A term now popularly used to describe the increased use of web-connected industrial processes, which employs software, robotics and advanced automation for greater productivity, quality and efficiency, Industry 4.0. is revolutionising the factory floor.

According to a government commissioned review published in 2017, Britain's manufacturing sector could benefit by as much as £455 billion and enjoy a net gain of 175,000 highly skilled, well paid jobs if, over the next ten years, it is able to unlock the value associated with Industry 4.0.

However, we recently commissioned a survey of senior decision-makers across a range of businesses, including manufacturing, which revealed that a high proportion don't recognise the benefits of automation and digital technology, or acknowledge the role that digitalisation now plays in manufacturing. Despite the evolution in manufacturing technology and processes, and the opportunities this represents, only one in ten of the respondents claimed to see any association between manufacturing and Industry 4.0, and one in five businesses said they believe the sector is currently unprepared for what Industry 4.0 entails.

A question of perception

Manufacturing businesses appear to be embracing the benefits of automation and digital technologies to a greater extent than those in any other industry right now. Cutting-edge techniques such as CNC machining, metal 3D printing, and rapid injection moulding enable manufacturers to produce components in as little as a single day from the submission of an original CAD design.

None of this has prevented the industry from suffering from something of an image problem, though.

Many organisations have an outdated view of manufacturing, believing it to be neither high-tech nor digital-savvy. Indeed, the survey found that the industry was still associated by around a quarter of senior business decision makers in the UK with legacy terms including "assembly lines" and "manual labour".

And, contrary to the growing volume of headlines which espouse robotics and automation as the future of the industry – for good or for ill - a quarter of businesses expect to see little or no increase in the use of automation in their manufacturing services over the next five years. Ultimately, holding a view such as this is likely to restrict the competitiveness of UK businesses, with those that overlook automation failing to enjoy the cost and time savings it offers.

But it's not all doom and gloom for manufacturing, however, with businesses believing that investment can deliver a bright future the industry. Almost half of the decision-makers that responded to the survey suggested that investing more in R&D was needed for the UK to retain its position in the global manufacturing market, and a third said they supported a greater focus on attracting graduates in STEM subjects (science, technology, engineering and maths) as a means of developing fresh talent and bolstering the industry's growth.

An industry powered by innovation

The growth of digitalisation, and the benefits offered by digital technologies and automation are transforming the manufacturing sector. Industry 4.0 isn't some elusive, futuristic concept; it's happening now but, rather than shying away from it, it's something we should be welcoming.

However, the results of this survey suggest that there is a limited understanding of Industry 4.0 and the impact it has already had, and will continue to have, on the progress of manufacturing. It is somewhat concerning to learn that manufacturing in the UK isn't being more widely seen as an increasingly high-tech, digitally-powered industry that can propel many British businesses forward, along with the wider economy. Instead, the inherent perception remains of manufacturing as largely manual work, made up of labour-intensive processes.

The reality is that the UK's manufacturing industry is powered by innovation, and driven by entrepreneurs and some of the country's most highly-skilled engineers, employing advanced automation and digital technologies to ensure production-ready parts can be delivered at volumes, speeds and levels of quality previously unimagined.

Those businesses not directly using automation or automated processes should not overlook this trend, and should consider instead that automation, in some guise, can drive both cost and time savings for all businesses in the long run. Indeed, it could be argued that those companies that aren't employing automated processes or digital technology could be placing their business at a disadvantage in today's fast-paced competitive climate.

We can't afford to ignore the rise of these technologies, the transformative effect they're already having on the sector, and the opportunities and benefits they represent. Instead, it's now time to recognise the crucial role that digital technologies play in ensuring the UK's manufacturing industry remains competitive. For those businesses yet to embrace these technologies, it's not too late. The future of manufacturing starts here.

Stephen Dyson is head of Industry 4.0, Protolabs.